Thesis Offers (B.Sc., M.Sc. and MAP miniproject)

The institute has the capacity to support a large number of Bachelor’s and Master’s projects in addition to MAP miniprojects. Below you can find some of the currently available topics. However, this list is not exhaustive and students should contact the individual research scientists who cover their topic of interest regarding potential project topics.

Thesis topics in the Nanostructured Particles Research Group (Prof. Klupp Taylor)

We are looking for highly motivated Bachelor’s and Master’s students to carry out projects in our group. If you find our work interesting and would like to know more about these opportunities then please contact Prof. Robin Klupp Taylor or the respective doctoral researchers in the group. Here are some specific open topics:

Bachelor/Master/Miniproject: Automated Image analysis and statistical processing of patchy particles

Contact: Robin Klupp Taylor

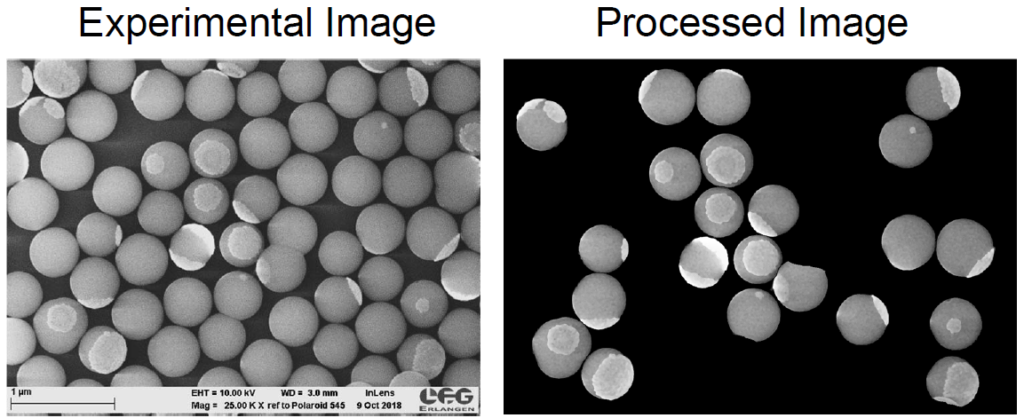

The nanostructured particles research group has developed a simple and scalable process to produce metal patches on core particles. Due to the nature of the processes, the patches have a size distribution and not all core particles get coated (see left image below). In order to further optimize the process to produce patchy particles with desirable properties quantitative insight into the patchy dispersity is required. In this project image analysis will be developed for this purpose. The project involves little or no practical labwork and is particularly suitable for students with some programming experience.

What we want: Image analysis codes to determine core size distribution, patch yield (fraction of particles with patch), thickness and coverage distribution

Starting point: real and simulated images of patchy particles and a code to determine which particles have a patch (see right image below)

Project objectives:

- Develop code able to segment and measure the core particle and patches.

- Develop an experimental protocol for obtaining well dispersed patchy particles, automatically acquiring images on the SEM and analysing them for patch yield and coverage

Tools:

- ImageJ

- Python

- POVRay

- Matlab

- Scanning electron microscopy

- Analytical (ultra)centrifugation

Bachelor/Master/Miniproject: Synthesis and properties of 'Janus Flakes'

Contact: Robin Klupp Taylor

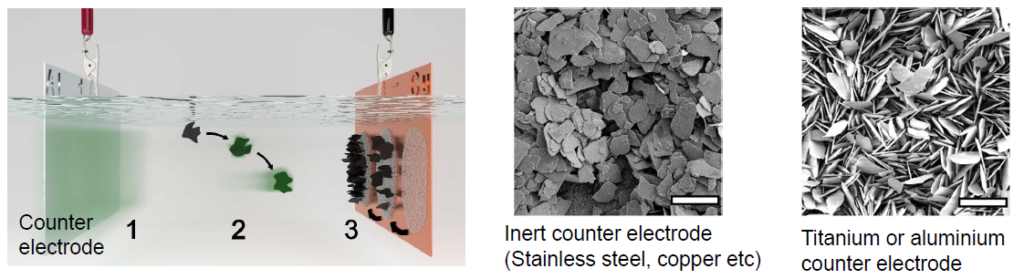

The starting point of this project will be a simple and robust process based on electrophoretic deposition (see Figure below) developed in the group. This process deposits flake-like particles (e.g. commercial mica powder) in an out-of-plane arrangement. In this project, the possibility to arrange flakes in this way will be exploited in order to partially coat the flakes i.e. produce “Janus flakes”. This will be achieved by masking the part of the flakes closest to the substrate with a suitable polymer, followed by coating of the exposed part of the flakes. Once the flakes are released, such partial coating could be used to give the flakes amphiphilic properties, enable catalytic self-propulsion or introduce an unusual optical or magnetic properties.

Project objective: Demonstrate that the out-of-plane oriented flakes can be further processed to produce novel functional particulate materials

- Re-commission previously established electrophoresis setup

- Establish desirable coating chemistry (polymer or inorganic material) on suspended flakes

- Establish partial flake masking strategy (already in literature for spherical particles)

- Show that coating chemistry can be applied to exposed parts of flakes

- Release flakes and characterise properties.

Tools:

- Electrophoretic deposition

- Particle coating methods (wet chemical synthesis)

- Thin film coating methods (spin-coating etc)

- Particle characterisation (DLS, analytical centrifugation)

- Optical microscopy and Scanning electron microscopy