Additive Manufacturing

Additive Manufacturing

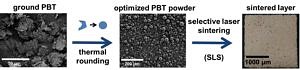

Spherical polybutylene terephthalate (PBT) SLS particles obtained by thermal rounding of wet-comminuted PBT particles in a heated downer reactor.

Additive manufacturing (AM), commonly referred to as ‘3D printing’, allows the tool-free and formless production of complex structures. Especially beam- and powder-based methods like selective laser sintering (SLS), selective laser melting (SLM) or selective electron beam melting are promising. So far, especially for SLS of polymers the current choice of commercially available powder materials is very limited.

The aim of our research is the development of scalable process routes towards production and functionalization of novel particle systems for additive manufacturing. In the case of polymer particle systems, for example, wet grinding, melt emulsification or liquid-liquid phase separation and precipitation are applied for SLS powder production. Moreover, we investigate gas phase functionalization processes for the tailored modification of powder properties such as particle shape, flowability, and surface chemistry as well as thermal, optical and electric properties by thermal particle rounding, dry particle coating and plasma enhanced chemical vapor deposition (PECVD). Moreover, techniques for appropriate chara

cterization of powder properties relevant to the AM process including the evaluation of powder flowability, thermal, rheological or triboelectric properties of the materials are utilized and developed.

Projects:

- Liquid Phase Production of Functional Polymer Particles

- Modification and Functionalization of Powders in Gas Phase

- Quality assurance system for powders used in selective laser beam melting of polymers